To achieve straight surface of steering rack we have done RACK STRAIGHTENING MACHINE using hydraulic press. In this Machine PLC Interfaced Embedded system to find the exact position of the bend at the rack by LVDT & Rotary Encoder

To insert the Rack & Valve during steering assembly, we have done RACK&VALVE ASSEMBLY STATION. During this assembly it automatically apply grease & exactly rotates the position of the rack to insert the valve for both LH & RH Models using Servo system.

To insert the I/P Shaft Seal & Circlip during steering assembly, we have done a SPM INDICA&INDIGO I/P SHAFT SEAL, CIRCLIP ASSEMBLY STATION. During this assembly Seal insertion Position & Circlip insertion Position achieved exactly Servo system & also Seal & Circlip Insertion Load Maintained using SYSCON Load cell.

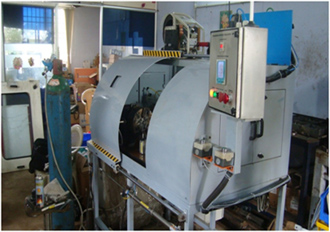

During steering assembly to insert NRB, Ball Bearing, Pinion Seal, Ring Rack & Rack Seal on Housing & Racktube we have done a SPM L90 1ST STAGE AUTOMATION. During this assembly all the insertion parts Position are achieved exactly by Servo system & also Insertion Load Maintained using SYSCON Load cell.

It is used to deburring the steering rack hole, Accoring to the Height of the Rack Deburring hole length will be automatically adjusted, Servo system is used to achieve the position & LVDT is used to Compare the Rack Height.

It is used to drill a cross hole of 3.2mm on Fly Wheel Housing. which is called Lubrication hole.

In Transmission & Distribution of Power system ALSTOM T&D Ltd requires Flexible Increment of Sheet Length at the accuracy of unit in mm. For that We made a machine with Servo & Hydraulic Cutting System. In this Machine Servo will gradually increase length of the sheet Hydraulic will cut it. For operator Safety Photoguard (Light Curtain) systems implemented near cutting system.

This Machine done for brake shoe size forming i.e., after weld shoe has some twist, to rectify that shoe will go under this process.

This Machine done for Hydraulic Cylinders assembly automation

We have done a complete steering assembly line, for RANE(MADRAS)LTD, Thirubhuvani, This line includes nine assembly stages . For operator Safety Photoguard (Light Curtain) systems implemented at each stage which protects fingers, hands and ankles. SCADA (Supervisory Control and Data Acquisition) offers Acquisition of data of each stage using BARCODE sticker & also Logs History Of alarms. To improve the accuracy of assembly we have interfaced servo system which achieves exact position with high speed

It is used to find the crack on seat belt buckle. Lab View with MODBUS Communication has been used for this Project.

This SPM is used to find any leak in Fly Wheel Housing. It is a Dry Leak testing System. Where, ATEQ Leak Detecting Interfaced with PLC.

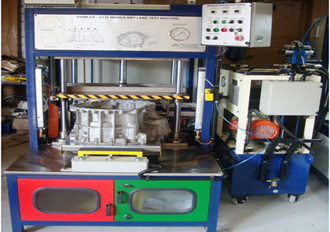

This SPM is used to find any leak in Rack tube which is used for steering assembly. It is a Wet Leak testing System. Where, PLC & Analog Modules are used to find the Leak.

These Machines are used to find any leak in Fuel Filling Line. which is used for Fuel Tank assembly. Both are Wet Leak testing Systems. Where, PLC & Analog Modules are used to find the Leak.

This Machine done for weld the push rod & plate which is used in brake system called spring brake actuator (SBA). Client: Wabco-India Ltd.

It is used weld the BOSS on RACK TUBE which is used in Steering system.

This Machine is used to for VALVE HOUSING & BUSH PRESSING. Where, Hydraulic System is used for Pressing.

This Hydraulic based Machine is used to for Die Casting.